With more and more companies coming up with sustainable cladding options, there’s no reason not to go green. Here are just three examples.

1 Super-Thin Steel

Scheduled for completion in 2020, Harvard’s new Science and Engineering Complex in Boston will feature a unique, energy-conscious folded steel facade. The local branch of Behnisch Architekten collaborated with German fabricator Josef Gartner of Permasteelisa Group to develop a finely calculated cloaking system that incorporates hoods to shade the building from direct sunlight at every angle.

Architect Matt Noblett of Behnisch notes that the team referenced the operable exterior screens that have long been used in Europe, but created a fixed version that does not rely on mechanisms that could eventually break down. Gartner proposed hydro-forming to achieve ultra-thin panels that could be folded in at the corners to shield from heat gain and then perforated to mitigate glare, thereby alleviating heating and cooling loads.

A total of 13,000 panels will be installed to create modules that are six storeys tall and only 1.5 millimetres thick. The screening will not detract from views out, and from the street it will give the building a “scale-less character.”

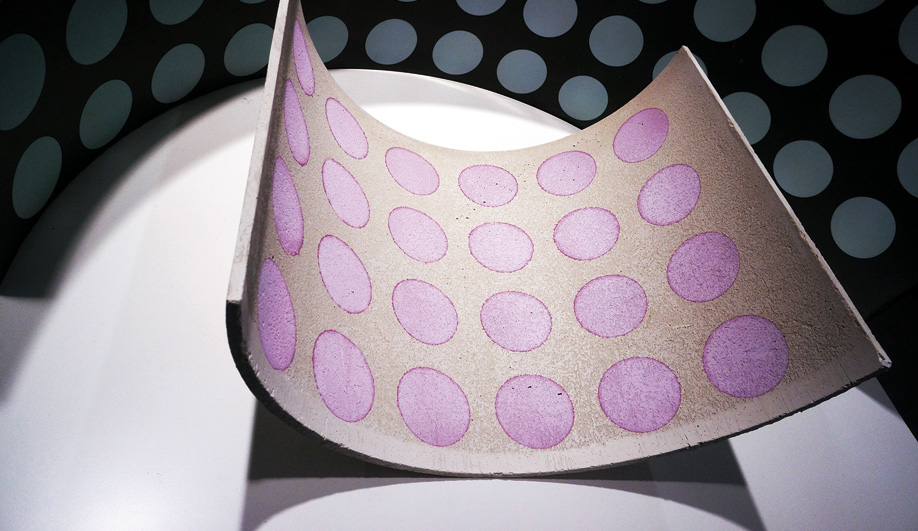

2 3D-Printed Composites

To address housing shortages on a micro-scale, Emerging Objects of San Francisco is experimenting with a 3D-printed facade and rain screen that can be affixed to an existing structure, like a garden shed, potentially upgrading it to a weather-tight, livable dwelling. Printed from a filament containing concrete, sawdust and pomace (grape waste from wine production), the hexagonal plates can be planted with succulents, while the ceramic roof and siding shingles are quick to produce and easy to assemble.

3 Solar Concrete

By incorporating natural dyes that absorb light to transform it into electricity, Dyscrete essentially turns concrete into a living organism that performs a process similar to photosynthesis. In development by the University of Kassel’s Building Art Invention platform since 2015, the material is based on dye-sensitized solar cells, which are typically applied to glass. The research has resulted in a non-toxic spray-coat method that “generates energy through an electrochemical process when exposed to light” and can be sprayed in-situ.

This story was taken from the June 2018 issue of Azure. Buy a copy of the issue here, or subscribe here.